For two and a half days in October, the Georgia World Congress Center became the epicenter for the world of print. Printing United is the only place where the entire print industry comes together under one roof, and it descended upon Atlanta, Georgia featuring exhibits, education, demonstrations, networking and events.

This expo includes the world of apparel decoration, commercial publishing, graphic installers, wide-format, in-plant, labels, packaging and many other forms of printing. In fact, this show is about much more than just printing – embroidery, laser ablation, heat application, consumable supplies and tech services are also heavily featured on the show floor.

While we would love to highlight everything we learned while in attendance, here were a few of our biggest takeaways — there’s a lot to cover so feel free to jump ahead to the topic that interests you most.

- Direct To Film (DTF)

- STAHLS’ Annoucements

- New ROQ Equipment

- Inkcups New XJET Switch

- Atlas Max Poly from Kornit

Direct to Film Storms the Floor

There were no fewer than 35 Direct To Film (DTF) pieces of equipment on the Printing United floor this year. This decoration method has exploded in scale and popularity, and apparel decorators are finding it a low-cost buy-in option for their shops.

SPSI

Minnesota-based SPSI was on-hand to showcase two of their flagship products; the Velox DTF and Solis Inline UV DTF printers.

SPSI has a strong focus on service and support for their client base and anchored their presence with a transparent look into exactly what that process looks like. Should the need for support arise, a customer can use SPSI’s online portal to communicate their challenge and will receive a rapid response back via video troubleshooting, over-the-phone assistance or a virtual call from one of their technicians. In a field where the technology is relatively new this makes SPSI an attractive option when considering a major purchase; they have the workflow in place for the consumer to feel confident in the support they will receive.

Velox DTF

The Velox has a white ink system with two standout features that operate in tandem; an ink mixing system with two white ink recirculating systems. It also features a heated vacuum bed that will keep the film carrier flat and tracked straight during production. This heat element allows the Velox to print much faster than most units.

The Velox has a white ink system with two standout features that operate in tandem; an ink mixing system with two white ink recirculating systems. It also features a heated vacuum bed that will keep the film carrier flat and tracked straight during production. This heat element allows the Velox to print much faster than most units.

The Velox will also print “confidence strips” on the left side of the film carrier during production, color bands which guarantee that every nozzle is firing on every pass of that printing head. This allows you to do white ink printing for hours without stopping and cleaning, so you can then switch directly over to a full color graphic with no issues.

The Velox’s Wasatch RIP software features easily customizable print settings with multiple profiles for different jobs, depending on the logo and substrate being used. Most logos can be printed in a six-pass print with a 90% white base, which leaves a crisp and not oversaturated print. The ability to limit the amount of white applied will also result in a better hand feel.

Solis UV DTF

Meanwhile, the Solis Inline UV DTF Print Lamination System is an intuitive piece of equipment that features a piezoelectric printhead and prints high-quality graphics directly onto the adhesive backing of a clear film roll. These graphics are extremely simple to apply — you only need to peel off the film and apply the sticker to create whatever custom product you want. These stickers are wonderful solutions when decorating hard good categories, such as drinkware, bottle openers, card holders, etc.

Meanwhile, the Solis Inline UV DTF Print Lamination System is an intuitive piece of equipment that features a piezoelectric printhead and prints high-quality graphics directly onto the adhesive backing of a clear film roll. These graphics are extremely simple to apply — you only need to peel off the film and apply the sticker to create whatever custom product you want. These stickers are wonderful solutions when decorating hard good categories, such as drinkware, bottle openers, card holders, etc.

The images have been tested to withstand rigorous wash cycles in a home dishwasher and will fully set and mold to the substrate within 24 hours. The Solis can print in a matte or gloss finish, and features CMYK with White and varnish to supply vibrant, unique dimensional effects.

M&R Quatro DTF

M&R Quatro DTF

M&R has long been a leader in the space of screen printing equipment (such as the release of their brand new Gauntlet 4 Automatic Press) and over the years we’ve seen a lot of new digital creations come out of their lab, including the DS-4000 Digital Squeegee and Polaris.

The aptly-named Quatro is the fourth segment of M&R’s product offering and made its debut at Impressions Fort Worth in September. It features a 24” high-resolution industrial inkjet printer and comes with a PC workstation, an intuitive interface and its own Quatro HP RIP software, powered by Caldera. Four Epson i3200 print heads (2 CMYK and 2 White) make up the bulk ink system with white ink circulation. Perhaps most importantly, the Quatro features an integrated exhaust filtration system, allowing the user to simply filter the exhaust instead of porting it into a dedicated box or through an exterior wall/ceiling. It also features M&R’s Positive Link System to ensure accurate film tracking between the Quatro printer, powder applicator and dryer.

Brother GTX Roll 2 Roll DTF

Since Direct To Film hit the scene several years ago, many Brother GTX DTG shops have been modding their printers into DTF-friendly machines. By feeding in a single sheet of film, and applying the adhesive powder by hand, the user simply needed to feed the completed print into a small dryer for curing to achieve a DTF print. Brother even went so far as to create a PDF Guide on how to perform this process.

Since Direct To Film hit the scene several years ago, many Brother GTX DTG shops have been modding their printers into DTF-friendly machines. By feeding in a single sheet of film, and applying the adhesive powder by hand, the user simply needed to feed the completed print into a small dryer for curing to achieve a DTF print. Brother even went so far as to create a PDF Guide on how to perform this process.

Now Brother has taken it upon themselves to bring an automated roll to roll solution to market with their Brother GTX R2R.

This DTF printer features two of Brother’s 4-channel piezo on-demand print heads with internal fans to help keep ink consistently flowing. In addition, the adhesive application and curing device has a built-in ionizer, and an infrared curing system for effective application across 16 inches of print width.

Brother’s workflow automation allows you to save time with features that remove background colors, automatically resize your design, nest intelligently and utilize barcodes to track your product at every step along the way. Brother has also incorporated their Innobella Textile Inks into this piece of equipment, which allow you to create specific profiles for specific designs.

If you’re a fan of Brother’s support system you’ll be happy to hear that you receive the same Certified Brother technicians, as well as Brother Academy’s online support resources, should you need any assistance.

Mimaki TxF300-75 DTF

Mimaki TxF300-75 DTF

Mimaki’s second foray into the world of Direct to Film brings a CMYK plus white printer, with an 800 mm print width that offers three times the productivity of its predecessor.

Higher print speeds mean more capacity for output, and that’s the name of the game for this next gen Mimaki printer which is compatible with various inline powder shaker/curing units.

Mimaki’s PHT50 pigmented inks are incorporated into the fold, which are Eco Passport-certified, and bolster against negative environmental impacts while meeting the strict requirements of Oeko-Tex certification. The Mimaki TxF300-75 also features an integrated ink circulation system designed to prevent white ink from clogging, and a degassed ink set that reduces the risk of faulty ink ejection.

The TxF300-75 also boasts both a Nozzle Check Unit and Recovery System, which will automatically inspect and detect clogged nozzles to initiate cleaning and recovery. If the Check Unit can’t recover the clog, then the Recovery System kicks in and will substitute the defective nozzles with operational nozzles to ensure an uninterrupted production pace.

STAHLS’ Announces Fulfill Engine Acquisition and Introduces New ProPlace IQ

STAHLS’, known for their innovative heat transfer technology and hardware, had several big announcements at Printing United this year.

STAHLS’ first announcement was the joining of GroupeSTAHL Global, which means that STAHLS’ has increased their brand worldwide to bring consumers the same consistent product regardless of country or continent.

STAHLS’ also made headlines by introducing their newest addition to the GroupeSTAHL family; STAHLS’ Fulfill Engine. Fulfill Engine specializes in order fulfillment, supply chain management, and e-commerce store integration. With Fulfill Engine, STAHLS’ will make order fulfillment more efficient, expansive, and effortless for decorators. This platform will allow you to outfit white label stores or Shopify integration and bring orders into your business.

By scanning a QR code you can automatically source blank apparel from SanMar, and heat transfer supplies from STAHLS’ without having to go to the vendor’s website. When those goods are received, placing a label with that QR code onto the garment integrates it with the job across all necessary departments of your facility, all the way through outbound shipping where a simple scan of the QR code will print the shipping label for you. STAHLS’ Fulfill Engine looks to become an extremely versatile piece of software to enhance a shop’s production, sourcing, e-commerce, and efficiency processes in early 2024.

By scanning a QR code you can automatically source blank apparel from SanMar, and heat transfer supplies from STAHLS’ without having to go to the vendor’s website. When those goods are received, placing a label with that QR code onto the garment integrates it with the job across all necessary departments of your facility, all the way through outbound shipping where a simple scan of the QR code will print the shipping label for you. STAHLS’ Fulfill Engine looks to become an extremely versatile piece of software to enhance a shop’s production, sourcing, e-commerce, and efficiency processes in early 2024.

STAHLS’ also launched their newest piece of hardware in the Hotronix brand; the STAHLS’ ProPlace IQ. This piece of equipment attaches to the Hotronix Dual Air Fusion and will be officially released in Q1 2024. You’ll be able to purchase this separately if you already own the Dual Air Fusion, or as a combined purchase solution with both.

The ProPlace IQ connects to the IQ Cloud software, where you can load the design file that you want to create and press. You will be shown an example of the 16”x20” platen, where you can then align and center the image and have it projected onto the platen; centered, straight and ready to be applied to the garment of your choice.

This gives the decorator confidence that their heat application is not misaligned from the first shirt through to the end of the job. The projection of your image allows you to quickly place your transfer logo while eliminating the guesswork. Switching to different designs that are already uploaded into the IQ Cloud software is as simple as tapping the desired image file, and the projector will automatically move on to the next file on demand.

ROQ Debuts Four New Equipment Stories

The Portugal-based industrial company ROQ has made a name for themselves across the United States as a premier provider of screen printing and digital equipment. They have become known for advanced technology, user-friendly equipment, and a cool vibe that resonates with both young apparel decorators and seasoned printers looking for a change of pace.

Alongside some of their quintessential success stories, such as the ROQ NOW and ROQ SAHARA, ROQ US introduced four brand new chapters to the ROQ catalog of equipment at Printing United 2023.

ROQ OUT

ROQ OUT

Earlier this year we featured the ROQ FOLD and its companions in our article about Impressions Atlantic City. The ROQ OUT is a new alternative solution for the decorator that needs a fold/pack/label solution for tees and lighter weight garments, which is especially ideal when operating within a much smaller space.

The ROQ OUT is a compact, automatic machine capable of folding, packaging, and labeling up to 350 pieces per hour in a footprint less than half that of the ROQ FOLD and its ancillary equipment required to achieve the same results.

A single operator can slide a garment onto the automatic folding unit, while a poly bag is positioned and opened by an air blowing piece of hardware on the other side of the machine. The garment is then automatically fed into the open bag, the bag releases and is stamped with a label for shipping. The bagged and tagged garment is then directed towards a slide where it makes its way back down along the side of the ROQ OUT and conveniently at the operator’s hip for easy packaging.

The ROQ OUT is an ideal solution for the decorator that has a heavy emphasis on tees, jerseys, or polos looking to minimize footprint during post-press and save some money in the process.

ROQ E

ROQ E

The “E” in ROQ E stands for Electric, which is the only thing one needs in order to operate ROQ’s newest automatic press. It’s available in an 8 station/6 color model, and 10 station/8 color model. Similar in size to the ROQ YOU, the ROQ E does not require any air connections or access to an external air compressor for operation. It also features low profile pallet arms for easy sleeve printing.

The novel component of the ROQ E is the built-in air compressor that is contained within the unit itself, making it the first ever self-contained automatic screen-printing machine. The central lifting system is 100% electric, while the built in air-compressor only needs to turn on after several cycles to power the print heads.

The print arms can be individually raised and locked in place, allowing instant access to the print head and under carriage for each arm. This allows for easy cleaning, flash unit installation or to simply remove the screen itself.

Capable of running 800 pieces per hour, the ROQ E is a great fit for a shop looking to maximize their space and reduce their volume level.

ROQ IMPRESS

ROQ is also taking advantage of the new equipment and materials boom with their first foray into automated heat-applied technology. The ROQ IMPRESS is ROQ’s answer to the carousel-style automated heat press machines that have started to pop up over the last 12 to 24 months.

It can produce up to 500 pieces per hour, saving a substantial amount of time and streamlining the heat transfer application process through the use of a circular machine, rubber top pallets, and up to three heat presses. The carousel press features a loading station, followed by a pre-press head to remove moisture and lay garment fibers flat. A laser marking system ensures straight and centered application of the transfer, which then moves into the heat press application station, an optional second press station and finally the unloading station.

Applications for player numbers, vinyl, cad-cut and add-ons like twill, rhinestones, foil, transfers, Direct to Film and more can now be applied using this new innovation from ROQ.

ROQ READY

Rounding out ROQ’s lineup of new equipment at Printing United is the ROQ READY, ROQ’s answer to the automated carousel pre-treat process for Direct to Garment production. Especially efficient when combined with ROQ GO, their DTG single pallet machine.

This is an ideal solution for digital garment decorators that want a fast, efficient, contained pretreat application that’s capable of accommodating different formulas. The ROQ READY features two different pretreat modules — one for light garments and one for dark — in addition to heat presses and flash units to create a fully inline pretreat, flash cure, heat pressing carousel. This unit can pretreat up to 250 garments per hour and allows you to store unique recipes in the unit’s control panel based on the garment type.

The ROQ READY expands upon ROQ’s growing arsenal of digital equipment as they nimbly navigate the changing landscape of garment decoration.

Inkcups’ Highlights their New XJET Switch

Inkcups, known for their highly innovative technology in the world of Cylindrical Inkjet Printers, Pad Printing Machines, and Tagless Printers has officially launched the new XJET Switch (Winner of Printing United Alliance’s 2023 Pinnacle Technology Award) into their UV Flatbed line of products.

Inkcups, known for their highly innovative technology in the world of Cylindrical Inkjet Printers, Pad Printing Machines, and Tagless Printers has officially launched the new XJET Switch (Winner of Printing United Alliance’s 2023 Pinnacle Technology Award) into their UV Flatbed line of products.

The XJET Switch is a specialized UV flatbed printer that optimizes full-color prints via their XFLEXX UV Inkjet Series and directly onto reusable bags, hard goods and more. It leverages the power of UV curable inks and advanced digital printing technology to enable seamless production of vibrant, high-quality prints directly onto flat surfaces. Perhaps most importantly, digital UV printing reduces materials, energy and waste, making the XJET Switch a more sustainable alternative to decoration.

This new unit from Inkcups features a total print area of 13.8 inches x 25.6 inches with a maximum part height of 8 inches tall.

The XJET Switch also has a patented continuous printing technology which enables the operator to load products while the machine is in operation, optimizing production efficiencies and volume capacity. Upon completion of the printing process, the table will shift to the front position, allowing unloading of the finished items and subsequent reloading for continuous production. Say goodbye to wait times as you continuously load the printer for its next batch while it completes the prior task.

Safety for machine operators has also been emphasized with anti-crash sensors to safeguard the print heads from unexpected collisions, as well as a state-of-the-art intuitive light curtain system which has been designed to ensure operator safety during production.

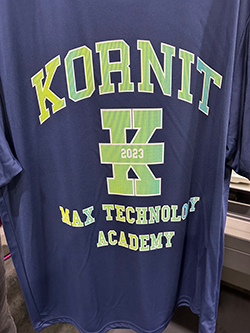

Kornit’s Atlas Max Poly Revolutionizes Digital Printing on Synthetic Fabrics

Another winner of the Pinnacle Technology Award, Kornit’s Atlas Max Poly was a digital titan on the expo floor that drew consistent attention from onlookers and potential buyers alike.

Another winner of the Pinnacle Technology Award, Kornit’s Atlas Max Poly was a digital titan on the expo floor that drew consistent attention from onlookers and potential buyers alike.

The Atlas Max Poly is Kornit’s specialty flagship solution for DTG printing on polyester fabrics and boasts an impressive rate of 90 printed dark garments per hour, with an average print time (including loading/unloading of the garment) of less than one minute. The system can be run by a single operator, and features an ink set that is capable of curing at temperatures as low as 230 degrees Fahrenheit, drastically reducing the risk of dye migration.

To accomplish this tall order, Kornit has developed a process that utilizes specially-designed consumables to achieve desirable results on polyester. These include the Proguard, which protects white solid areas from the effects of dye migration, the Q.Fix, jetted alongside the inks to boost print quality and prevent bleeding and ghosting, and the Intensifier, also jetted alongside the ink to increase curability at lower temperatures.

The printer carriage features 21 print heads to deliver all the required ink and specialty ingredients, including CMYK, White, Neon Yellow, Neon Pink, and these added consumables.

Two platens are included on the machine, allowing double the production capacity and the incorporation of two different designs and garment types while printing. While being able to decorate digitally on poly fabrics is certainly the machine’s standout capability, being able to effectively print on other fabric types (such as cotton and blends) should not be overlooked. The traditional platens are a great solution for t-shirts, jerseys and pullovers while the addition of alternative platens allow for decoration of sweatshirt fleece, leggings and more.

Two platens are included on the machine, allowing double the production capacity and the incorporation of two different designs and garment types while printing. While being able to decorate digitally on poly fabrics is certainly the machine’s standout capability, being able to effectively print on other fabric types (such as cotton and blends) should not be overlooked. The traditional platens are a great solution for t-shirts, jerseys and pullovers while the addition of alternative platens allow for decoration of sweatshirt fleece, leggings and more.

The Atlas Max Poly features a proprietary hardware called the Air Knife. During the pre-print process, this blows extremely hot air, reaching temperatures of up to 900 degrees Fahrenheit, onto the external layer of the fabric. This removes loose fibers and creates a smooth, ideal surface for printing, even allowing for decoration on brushed polyester fabrics. There is also a built-in wrinkle detection system which will notify the user if the surface of the fabric isn’t even and may cause damage to the printheads.

While the ability to apply standard prints digitally on synthetic fabrics should seem like enough, Kornit has gone the extra step by incorporating two additional innovative applications.

The first is Kornit’s XDi Technology, which allows the user to print 3-D designs and create special effects that mimic current trends such as high density or embroidery. This function allows the decorator to provide higher value prints without requiring any specialty ink set or hardware – the operator simply needs to select the required setups prior to printing.

The second application is Neon Colors. With the two neon inks that are incorporated into the printer carriage, the Atlas Max Poly can create unique neon prints with no major adjustments to the overall setup. These neon inks are also enhanced to glow under a blacklight.

With all this in mind, Kornit’s Atlas Max Poly has brought some truly revolutionary innovation to the world of digital decoration.

See You in Vegas!

The Printing United Expo returns to the Las Vegas Convention Center in September 2024. SanMar’s Decorator & Digital Solutions Team will be on hand to gather all of the big stories, announcements and events taking place. We hope to see you there!