“Wowzers!”

“Oh my gosh!”

“Holy moly!”

Those were just some of the reactions to the size and scope of this year’s record-setting Printing United show in Orlando.

The show has boomed since the pandemic thanks to the increasing infusion of members from the promotional products industry and a cross-marketing relationship with ASI.

The Biggest Printing United Yet

- Over 30,000 attendees

- 838 exhibiting companies

- 7 million pounds of equipment

- Over 100 educational sessions & presentations

- More than 300 attendees at the Women in Print Alliance luncheon

Stats via Printing United

It’s easy to feel lost among all the equipment at such a massive show. Our team of experts scoured the show floor—while there really was a lot to see and do, here are the five standouts that wowed us the most.

1. Melco meets on-demand needs

At a recent Stahls’ event, Melco stood out among the participating equipment companies with a massive number of single head machines. The machines were tethered and operating independently, and all interconnected with Fulfill Engine. Melco was (and is) clearly focused on meeting the growing decoration on demand momentum.

At Printing United, Melco showcased two technology systems:

- Summit is driving the flexibility of having multiple single heads producing the same job or having them run separate from one another.

- Fusion is a fascinating connection point to an e-commerce system. It empowers an end user to design and mockup realistic embroidery renderings and automatically create those files. It can truly help make on-demand embroidery needs even more favorable.

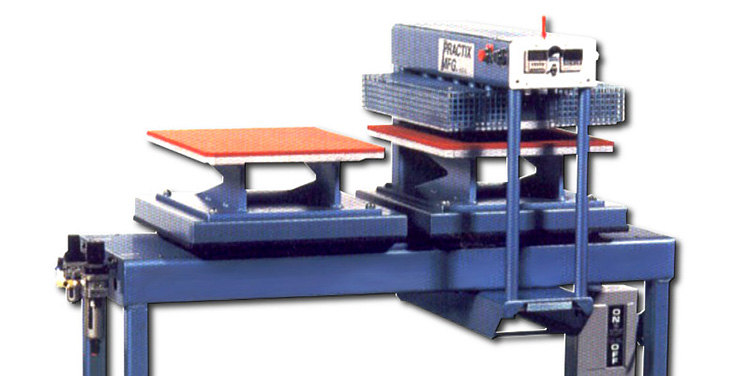

2. Practix MFG shares U.S.-made equipment

In a year of tariffs and overseas manufacturing uncertainty, equipment companies that build and produce domestically are worth a closer look. The Practix booth yielded several interesting U.S.-made discoveries:

- A shaker oven unit which cures the DTF transfer powder.

- A rotary heat press (a growing concept) that can produce 360 garments an hour and complements with their Place, Removal and Garment Stack additional equipment. This equipment looks to be brand new and not yet available to view on their website, so contact them for more info.

- A solution for embossing/debossing. This equipment is nothing new for Practix, but it was a great reminder that they have domestically produced options. One of the unique attributes to emboss/deboss is the setup process, involving machining metal “plates” that are used to create the image. Practix can handle this directly, shipping from their Atlanta-based office.

3. Mimaki enters the UV DTF arena

The Hirsch Solutions booth showed off the new UV DTF printer by industry leading company Mimaki.

UV DTF brings a new level of color, brilliance and on-demand-ready customization that is long overdue in the customization business.

The process involves printing the transfers in bulk with the freedom to cut and store for on-demand needs or apply them all at once with a two-step process. The finished product can go on drinkware, toolboxes, helmets, phone cases, and more.

The quality of the print and the strength of the adhesive yield long-lasting results.

4. Inkcups expands their reach

Continuing the trend of decorating on hard goods is a long-time champion in this space, Inkcups.

You probably know them for their pad printers and cylindrical printers. The newest member of the family is their X5-T High Throw Flatbed InkJet UV Printer. Unlike most options on the market, this equipment solves for limitations around the size and curvature of the item being printed on.

The X5-T can print up to a 25% curved surface—perfect for tumblers, sports balls, and coffee mugs. They feature a drop table option, which increases the overall space and allows for decoration on larger items, like full-sized basketballs.

5. The YET-TEE Stomper system offers DTF automation

DTF continues to dominate apparel decoration. So it’s no wonder some of the more exciting equipment debuting at the show answers the question: “How do I automate all the steps after the print?”

We’ve seen peelers, cutters, placers—all things independent from one another. But Brown MFG’s YET-TEE Stomper system automates the entire process.

This massive engineering marvel connects directly into existing DTF printers and handles everything afterwards, controlled by a single operator.

Many decorators have struggled with older heat presses, trying to understand how to better optimize the application process. This beast does it all. From Brown MFG:

The [YET-TEE] pulls exact cut transfers directly from the DTF printer, the transfer is powdered and then cured with the patented FireFly curing unit. The patent pending Flipper places the transfer onto the garment in the desired print location. The exclusive Linx software defines the location. Each garment can be unique with art, placement, and cure.

The garment is moved thru the Stomper Peel to remove the carrier sheet and placed in front of the single operator competed.

While the new equipment is very exciting, we were a little disappointed that its namesake failed to make an appearance. A real Yeti sighting would have capped off the day perfectly.

A new standard for Printing United

A show as impactful and massive as Printing United will always include way more new and exciting debuts than can be fully captured in one blog post. Hopefully, this has given you an idea of what’s new on the market and what you might want to check out.

If you’re deciding on new equipment and want an unbiased member of our team to talk over options, email us at decoratorsolutions@sanmar.com. We’re happy to help!

Printing United is expanding its reach into the promotional products channel. Next year will feature a massive promo pavilion specific to our industry.

If you’re thinking of attending, we encourage you to do so. Listen to the educational speakers, explore the apparel zone, and most importantly wear your walking shoes.

Want even more insights? Subscribe to the Printing United email newsletter for the latest.