The more time you spend as a screenprinter, the more you can spot the many ways a job can go sideways. One of those ways comes down to a simple choice: which platen adhesive are you using?

A great deal depends on this seemingly basic decision. As always, the Decorator Solutions team is here to help you figure out the right answer for you.

The Importance of Platen Placement

Here’s everything that needs to come together for a successful screenprinting run:

- The item being decorated must be placed onto the platen straight and centered.

- It needs to stay in place through the application of each color.

- The adhesive product you use should be compatible with your garment and production process.

- The adhesive must also be strong enough to compete with the natural stickiness of wet ink.

Any of these factors failing may result in misaligned colors or a blurred print. Using the wrong adhesive may also create inefficiencies, or even ruin goods during production.

There are several kinds of adhesives on the market you should consider, depending on the job you’re running. Let’s take a look.

Spray Adhesives

These are the most widely-used adhesives on the market, and have been around for a long time because they’re easy to apply. There are three kinds of spray adhesive:

- Traditional spray adhesive

Available in an aerosol can, made for easy application on to the platen when printing light-colored, cotton tees without the need for a flash. Fleece and textured fabrics are a challenge for this product—they release more fiber onto the platen and have less grip than traditional tees. - Flash spray adhesive

These adhesives are activated by the heat produced in flash cure units. Traditional adhesives can lose their tack after being exposed to heat, while this product will increase its tack as the job continues, making it ideal for long runs. - Web spray adhesive

This often-overlooked product may be the solution if fleece aren’t holding well, or other adhesives need to be re-applied after each print. Bonus: web adhesives typically keep the production zone cleaner because they have less overspray than a mist-style aerosol.

Be Careful!

These products—especially spray and flash-spray adhesives—can easily spread across your production floor during application. Thay can fall onto items nearby, including the screen itself or parts of your press.

You’ll want to keep your production area consistently clean and not let these adhesives build up in unwanted areas over time.

A final word of warning: spray adhesives can be extremely flammable. Be mindful of where these products are stored and regularly used. Failure to do so can have catastrophic consequences.

Water-Based Adhesives

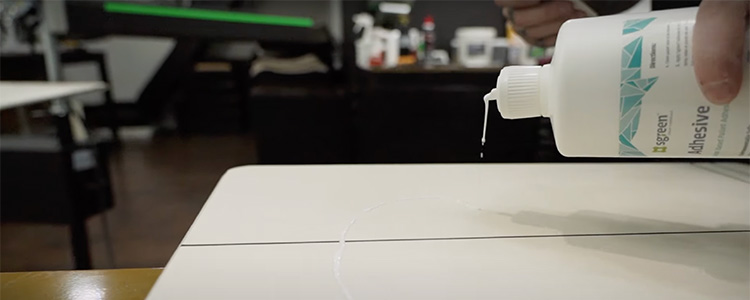

True to its name, water-based adhesive is a liquid adhesive that’s applied directly to the platen via a card/squeegee, roller or brush.

These adhesives tend to be budget-friendly, but require a bit more babysitting. They often struggle to hold tack when decorating heavier garments, such as fleece.

While decorating fleece with water-based adhesive can be accomplished, you may only be able to get through anywhere from 1 to 3 units per platen before needing to wipe the fibers off your platen and re-apply. This can be tedious and time-consuming, reducing efficiency.

On non-fleece fabrics, if tack starts to diminish, it can be reactivated with a wet sponge or spritz of water.

Take care not to be too heavy-handed with a water-based adhesive. Applying too liberally can result in warped prints due to excessive adherence, and stretching as you remove the shirt from the platen. Synthetic fabrics, such as 100% polyester or poly/spandex blends, are especially prone to this.

Sheet Adhesives

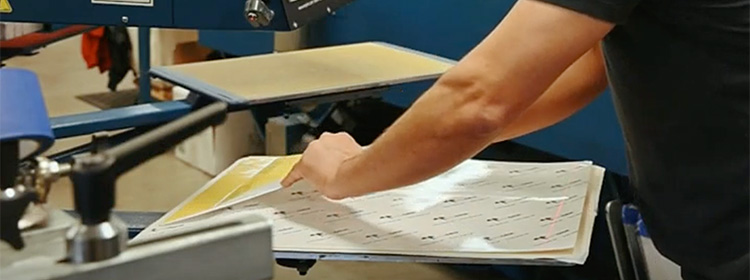

If you’re familiar with double-sided tape, then you know how sheet adhesive works.

This sticky application will arrive to you in either pre-cut sheets or whole rolls. Sheets are easier to work with and conveniently ready to apply to your platens, while purchasing a whole roll is less expensive in the long run.

This form of adhesive is great for a smaller shop that’s prone to shorter runs, as one of its primary drawbacks is that it doesn’t hold its tack for a long time. Unlike other adhesives, these sheets cannot have their tack reactivated by heat or water.

It’ll also be important not to keep these sheets on your press for very long. They’ll eventually become very challenging to remove, in addition to leaving behind an unwanted residue.

A relatively new product on the market has revolutionized the sheet adhesive landscape: PrintGRIP.

PrintGRIP has set out to create a safer, cleaner, and reusable alternative to traditional adhesive products. This is a 1mm polymer gel pad that has an unheard-of adhesive lifespan of 4 to 6 months before needing to be replaced. The only requirement is that you keep it clean on a regular basis.

Cleaning is simple, as 100% of the lint build-up can be removed with some water and wiping to dry.

PrintGRIP establishes itself as a more economic solution for platen adhesive, meaning less consumption, while also accommodating more hard-to-print fabrics, such as fleece and tri-blends.

Nylon and spandex fabrics should be tested first when using this product.

Follow this Advice to Form a Bond in No Time

Ultimately, it never hurts to be diverse in your shop. Having several different types of adhesive on hand for various print runs is beneficial, giving you more options to work with based on the needs of the project.

The world of platen adhesives comes with both pros and cons, so be sure to consider which adhesive is right for your shop and the type of garments that you prioritize.

If you have questions about which platen adhesive is right for you, or any other decoration conundrum, the Decorator Solutions team is always here to help.