Printing United has come and gone! While the tradeshow circuit took a heavy blow from the COVID-19 pandemic over the last several years, our Decorator and Digital Solutions Team was thrilled to see a heavy turnout at the nation’s largest print show. Two entire halls of the Las Vegas Convention Center were packed to the brim with printing and decoration equipment, solutions, technology and stories from across the medium.

Parked squarely in the Apparel Zone of the show floor, our team engaged with customers for three days, discussing new products, decorating techniques, and affiliate recommendations based on decoration method.

Speaking of affiliates, our team was able to walk the show floor alongside our customers and identify some of the biggest stories that the Printing United show had to offer this year. Here’s what our team found out — there’s a lot, so use the links below to jump to the topics you want to read about.

|

PosiPrint Takes Center Stage Equipment Zone’s Direct To Film Solution The Beautifully Compact Siser Juliet |

OvalJet’s DTG Thrill Ride Hybrid Digital Printing with M&R Inkcups Direct-To-Object Printers |

PosiPrint Takes Center Stage

As PosiPrint enters year two of its existence, word appears to have spread regarding the technology SanMar has developed to pretreat garments at the fabric level.

Throughout the entirety of the Printing United Show, PosiPrint styles were top of mind for many customers entering the booth that either currently operated with digital decorating technology, or who were interested in pursuing it.

Throughout the entirety of the Printing United Show, PosiPrint styles were top of mind for many customers entering the booth that either currently operated with digital decorating technology, or who were interested in pursuing it.

These three styles were featured in the Apparel Zone, a hub of digital decorating technology marrying blank apparel with direct to garment equipment. Throughout the show, our team was able to educate various tour groups that entered the space, as well as individuals seeking solutions for hassle free direct to garment options.

What’s more, affiliate partners Brother, Epson and Ricoh were all decorating live onsite within the Apparel Zone for interested attendees to observe.

It’s clear that as PosiPrint gains traction, these styles are beginning to create some serious buzz across the industry.

OvalJet Seeks to Revolutionize DTG Printing

Show attendees operating a large-scale shop with an interest in print-on-demand services were likely to navigate immediately to what was probably the show floor’s largest singular unit, the OvalJet.

With demonstrations happening at the top of every hour, show attendees would gather around this monster of a machine as start time approached, similar to a thrill ride at an amusement park.

With demonstrations happening at the top of every hour, show attendees would gather around this monster of a machine as start time approached, similar to a thrill ride at an amusement park.

And this thrill ride did not disappoint.

The OvalJet is a closed-loop technology, moving each garment around a carousel of 14 stations. Each of these stations prepares and prints the garments through a streamlined process which only calls for a single operator to achieve full size and full color prints of up to 240 shirts per hour; an unprecedented output volume in the world of DTG.

The garment’s journey begins at the load/unload station where a single operator loads the garment onto a platen prior to launch. Each platen features a full-size print location of 16” x 19”, plus a 3” x 4” in-line neck label directly above. This in-line neck print allows for no additional screen setups, or offline handling and optimizes each garment for custom branding while maintaining print speeds.

The garment then moves into the first of three Smart Press stations, which create a flat, warm, wrinkle-free surface that removes moisture from the garment.

Station three is OvalJet’s Digital Foundation/Pretreat, which features a proprietary foundation solution optimized for an ink-receptive layer for cottons and blends. This patented application method digitally jets the foundation in the exact size and shape of the design area, eliminating corrosion, over-spray, pre-treat box and staining.

Three Smart Cure stations follow. These act like flash units and create an in-line process that dries the foundation before the garment makes one more stop at a Smart Press station and moves on to printing.

As the garment rounds the far bend of the OvalJet, it enters the Digital White Cabinet which applies an evenly coated under base atop the pretreat foundation, moves into one final Smart Cure and Smart Press, then is finally exposed to the machine’s Digital Color Cabinet which features a CMYK+RG to deliver millions of droplets of ink at rapid speeds through Ricoh Gen 5 printheads.

The garment wraps up its journey in the Top Coat Cabinet and returns to the unload station to be removed for curing.

The garment wraps up its journey in the Top Coat Cabinet and returns to the unload station to be removed for curing.

The finished product was highly impressive, as the OvalJet team demonstrated the print’s durability through a 50-wash cycle test. The team also highlighted the OvalJet’s attention-to-detail print technology and showcased several nuanced detail differences within various designs that could be captured over several competitors.

The OvalJet can be installed on-site, and service technicians will train future operators on a standard operating procedure that includes use and maintenance of the equipment. Customers are also invited to join live monthly trainings that are recorded and shared for customer use. The OvalJet is backed by a one year warranty.

Equipment Zone’s EZ Jet Pro 24 may be the DTF Solution You’ve Been Waiting For

It’s no secret that the critical darling of decoration in the early 2020s has been Direct to Film.

As this new technology rapidly evolves and becomes more available, our team has consistently kept an eye and ear on any new developments that this technique has flowing through the pipeline.

Direct To Film has no lack of options. However, there are some caveats that a potential buyer may need to consider depending on their priorities, such as reliable performance, and consistent support should it be needed.

Equipment Zone has valiantly sought out a solution to quell all those concerns with their new EZ-Jet Pro 24. This Direct to Film machine features a 24” print width, with Epson print heads and a chip-free bulk ink system. There is no external exhaust needed, as the machine is supported by a built-in filtration system.

Equipment Zone has valiantly sought out a solution to quell all those concerns with their new EZ-Jet Pro 24. This Direct to Film machine features a 24” print width, with Epson print heads and a chip-free bulk ink system. There is no external exhaust needed, as the machine is supported by a built-in filtration system.

White ink is funneled through a recirculating system, and special attention has been made to the carrier tension on the back side of the machine to ensure that it doesn’t rebound on the print head and create clogging issues during print.

Not only did the performance of this machine highly impress us, but it was also a relief to hear that this equipment is backed fully by Equipment Zone’s highly touted unlimited support.

A purchase of this unit will include on-site installation and training (additional travel cost for locations over two hours away from major airports may apply) and is fully backed by a one-year warranty. To our knowledge, this is the first Direct to Film unit of its kind that is receiving this amount of support.

With this impressive display and commitment to customer, Equipment Zone has positioned itself to be a serious player in the Direct to Film game.

M&R’s Digital Squeegee Marries Traditional Screen Printing with Digital Technology

While we saw plenty of love from the world of Digital in the form of Direct to Garment printing and Direct to Film solutions, the M&R booth gave our team a demo in the world of Hybrid Digital Printing via their DS-4000 Digital Squeegee.

Hybrid Digital Printing is the mixing of a traditional screen printed underbase, with a digital CMYK overprint. This process reduces setup times and lowers the number of screens needed for multi-color prints. This means that shortened print runs can be profitable as digital data is quicker to generate, and able to switch on the fly when utilizing a common underbase.

Hybrid Digital Printing is the mixing of a traditional screen printed underbase, with a digital CMYK overprint. This process reduces setup times and lowers the number of screens needed for multi-color prints. This means that shortened print runs can be profitable as digital data is quicker to generate, and able to switch on the fly when utilizing a common underbase.

M&R’s Digital Squeegee is built as an extension compatible with their Stryker, Challenger III, and Gauntlet III presses. It features sixteen industrial printheads in a 16” array that provides a maximum print area of 16” x 19”. These printheads can produce images at resolutions up to 600 x 1200 dpi.

The DS-4000 inks are compatible with specially formulated inks for screen printing a white under base and utilizes the standard CMYK palette.

Shops can also incorporate a screenprinted discharge under base to remove the shirt’s dye and follow it up by laying down a Digital Squeegee print, thereby reducing the overall hand feel of the decoration and simulating a true Direct to Garment approach.

A massive benefit of the DS-4000 is that it can be used on virtually any fabrication that will accept high-solids acrylic water-based inks and can be cured using a tunnel dryer. M&R has successfully tested this process on cotton, polyester, blends, and performance fabrics.

For decorators running a high-volume shop that have an interest in incorporating digital elements into their portfolio for convenience and optimal hand, the Digital Squeegee DS-4000 is a piece of equipment that deserves attention.

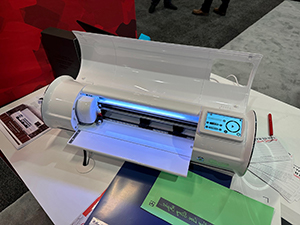

Siser Launches Their First Tabletop Cutter

After years of being an industry leader in the vinyl market space, Siser is embracing its Italian heritage with a lineup of aptly-named cutting hardware and software program companions.

The Juliet 12” High-Definition Cutter is a beautiful piece of equipment that packs a lot of features in a compact size that’s perfect for the crafting market.

The Juliet is designed for all Siser heat transfer vinyl and EasyPSV decal vinyl via its pre-installed cut settings. The cutter is also compatible with cardstock, stickers, craft foam and more. It features a maximum cutting width of 12 inches if utilizing the included cutting mat. Siser plans on launching a custom roll feeder soon, which will allow the user to go matless and cut longer rolls for larger designs.

The Juliet is designed for all Siser heat transfer vinyl and EasyPSV decal vinyl via its pre-installed cut settings. The cutter is also compatible with cardstock, stickers, craft foam and more. It features a maximum cutting width of 12 inches if utilizing the included cutting mat. Siser plans on launching a custom roll feeder soon, which will allow the user to go matless and cut longer rolls for larger designs.

Upon unboxing, you will find the Juliet 12” High-Definition Cutter, a power supply, USB cord, marker adapter, owners manual, setup card, a 12” x 12” cutting mat, a 45 degree blade, a 60 degree blade and compatible blade housing. The Juliet can connect to a PC or Mac via WiFi for a wireless experience, and features an attractive touchscreen user interface on the machine itself.

On the topic of production software, Siser has also created the Leonardo Design Studio, which was specifically made as a companion to the Juliet cutter, free with every Juliet purchase.

With Leonardo, the user can operate with a built-in canvas and tools to create their own custom artwork, or download premade files from a prebuilt art library that Siser has created. Swatches and specs for every Siser material are available for viewing, and Leonardo will also feature tutorial videos so the user can truly get the most out of their cutting experience with the Juliet.

A robust suite of cutting capabilities resides within an affordable purchase in this extremely attractive cutter from Siser.

For those looking to double up their cutting dimension capabilities, Siser has also released the Romeo 24” vinyl cutter as a larger scale option.

Inkcups Showcases Lineup of Digital Cylinder Printers and Compatible Software

Inkcups has long been an industry leader in the manufacturing of UV and pad printing equipment.

Inkcups has long been an industry leader in the manufacturing of UV and pad printing equipment.

For apparel decorators looking to expand their customizing options outside of the soft goods market, Inkcups brings a lineup of direct-to-object printers that are second to none. Already finding success with their Helix Digital Cylinder, and Double Helix Cylindrical Inkjet Printers, Inkcups had their Helix One on display for all show goers to witness.

The Helix One is the newest addition to this direct-to-object lineup of printers. It utilizes the patented Helix technology in a more compact design and can be positioned atop a table or bench to reduce shop footprint. This is a perfect option for small- to medium-sized companies looking to get into drinkware printing, without having to invest in one of the larger Helix models that Inkcups has in their assortment.

Like its larger brethren, the Helix One minimizes setup time with an advanced quick-change tooling fixture that can adjust to print on both straight and tapered substrates. Inkcups also offers a custom tooling service. You can send in some of your drinkware or cylindrical items, and they can create tooling that will custom fit perfectly onto the Helix rotary inkjet printer.

Like its larger brethren, the Helix One minimizes setup time with an advanced quick-change tooling fixture that can adjust to print on both straight and tapered substrates. Inkcups also offers a custom tooling service. You can send in some of your drinkware or cylindrical items, and they can create tooling that will custom fit perfectly onto the Helix rotary inkjet printer.

These Helix machines can print 360 degrees around a cylindrical object with a printable area of 218mm. The item spins under the printheads while the ink is laid onto the surface, which is then cured via UV light. It can print on items from 76mm to 305mm in length.

Inkcups provides a full support service, which ranges from documentation through to onsite training. One person is recommended for in-depth training to prep and optimize artwork, and should be familiar with Adobe products.

However, Inkcups does have a software solution formulated specifically for their digital printing equipment called ArtPrep. This is a subscription-based service, paid yearly, and is optimized to work with all Inkcups digital printers and workflows.

ArtPrep’s unique capability to seamlessly handle variable data, name drops, challenging gradient and highlights make it one of the most advanced image prep systems on the market. Not only does it take care of gradients, transparencies, and highlights, it gives you the unique capacity to control your ink costs through those settings.

Inkcups continues to deliver a robust offering of digital printing solutions on different materials and shapes, which can now be optimized by their own automatic artwork prep software, ArtPrep.

Until Next Year

The 2022 Printing United Show was full of amazing content and ideas on display, so much so that it would be challenging for any one person to truly fit it all in during the three day showcase. Whether you are an apparel decoration shop, a drinkware printer, an off-set printer or somebody looking for the next big revolutionary idea in digital printing, if 2022 is any indication, the 2023 Printing United Show in Atlanta, GA (October 18–20) is one to mark on your calendar.