During the pandemic, I’ve had time to learn about new software and processes that many decorators are considering. One decorator I spoke to said that they were looking into direct to film printers. This type of printing allows you to obtain simple, convenient consistency in performance with a wide range of colors, and these machines are now reliable and cost-effective to own.

What is a direct to film printer?

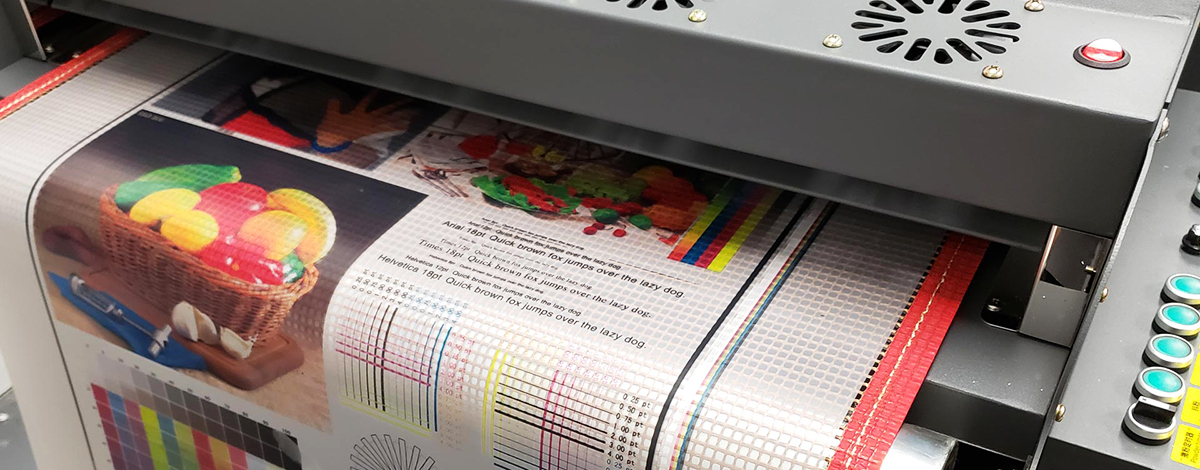

A direct to film (DTF) printer allows you to print a highly detailed design onto a piece of film, then transfer it directly to the fabric. The reason this technique is gaining status is the variety of fabric surfaces it makes available for printing. The DTF printer can print easily on cotton, polyester, synthetics or even silk with no issues.

How do DTF printers work?

DTF printers are equipped with multiple color ink tanks, allowing them to operate using CMYK settings. The printer ink is specifically designed for use with the direct-to-film process, which eliminates the use of rollers that could cause the page to slide and preserves the appearance of any lines on the white layer print.

A DTF printer uses PET films with a thickness of 0.75mm, making them better at transferring details than screenprinting. These films are also known as DTF Transfer Films in the market.

Software is an important element of direct to film printers. The printer software influences the color performance, print characteristics of the inks and final print performance. For this printer you will need a specialized RIP software to handle your white and CMYK colors.

DTF printing powder is a white granular product and works as the adhesive material which helps bind the colored pigments in the printer to the surface you are printing on.

A curing oven or a heat press machine is needed to melt the printer’s hot powder which then goes on the transfer film. If you only have a heat press machine, be sure to use it in no-contact mode. The heat press machine helps transfer the printed images from your film onto the desired fabric or surface.

Pros to think about investing in a direct to film machine:

- It does not require any pretreatment

- You can use it on almost any material or fabric

- Once the material is printed on you will still have a slight hand feel to the touch but it has shown great wash resistance