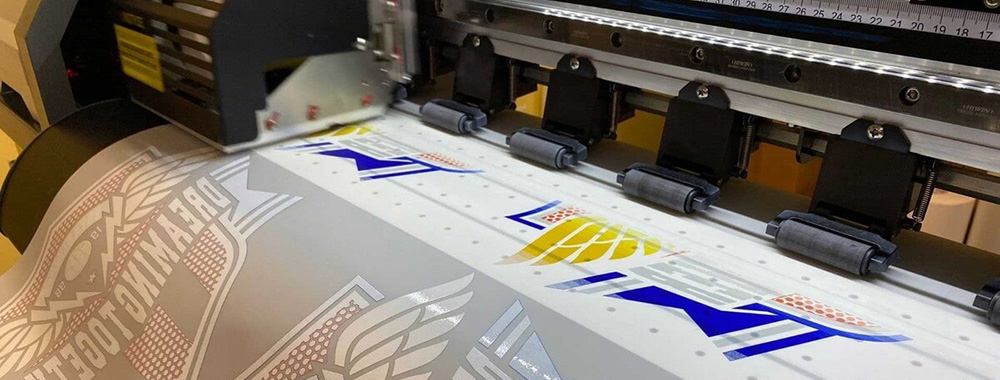

It seems like Direct to Film (or DTF) is everywhere these days. Given this technique’s versatile capabilities, it’s not surprising!

This type of printing allows you to print a detailed design onto a piece of film, then transfer it directly to fabric. DTF is popular due to the variety of fabric surfaces it makes available for printing, including cotton, polyester, synthetics or even silk.

As a decorator, you can either purchase outsourced DTF transfers or bring the whole process in-house. Let’s compare the two and see if it’s a good time to make the switch from buyer to producer.

Benefits of Outsourcing

Outsourcing DTF transfers can offer several benefits for decorators looking to enhance their printing capabilities without managing the process in-house.

- Lower initial investment. Instead of spending money on printers, inks and maintenance, decorators can pay for these services as needed. This is especially helpful to smaller businesses, because it manages cash flow and reduces upfront expenses.

- Expertise. Professional printing companies often have technicians who understand the nuances of the process and are familiar with the latest technology and techniques. This can ensure you’re receiving the best quality print possible. It also saves money by producing better prints with fewer mistakes.

- Flexibility. Decorators can adjust their needs based on demand without having to invest in additional equipment and staff. A decorator can increase their order volume during peak seasons without worrying about production capacity. This allows decorators to scale their operations efficiently.

The In-House Advantage

If you’ve decided that in-house DTF production might be right for you, here are some of the benefits you’ll see.

- Cost savings. Decorators can save money on outsourcing transfers to a third-party vendor and increase margins on their own prints. When paying a third party you’re paying for the transfer, plus any consumables used and labor. When printing in-house, you won’t be paying for the transfer house’s margins along with your consumable costs.

- Faster turn times. With in-house, decorators have more control over turnaround times by printing only their own transfers. When ordering from a third party, your order goes in a queue and gets printed when it gets to the front of the line. With in-house capabilities, a decorator can adjust schedules as needed based on demand.

- Quality control. Bringing the process in-house allows you to tightly control what prints are accepted and applied to a garment. When a customer receives a good-looking print for a decent price, it will keep them coming back! We recommend having two operators per machine: one to manage the printer and film, the other to cut gang sheets and inspect prints before going into production.

- Customization options. More customized options help attract business and differentiate you from your competitors. A decorator can quickly adapt to changing customer demands and market trends, and easily switch between different printing techniques and materials, depending on the needs of their clients.

- Increased revenue potential. In-house printing can open new revenue streams, allowing decorators to offer additional services such as on-demand printing, bulk transfer printing and drop-shipping. All of these can help increase overall sales and profitability.

How to Decide What’s Right For You

So now you’ve seen the benefits of both outsourcing transfers and printing them in-house. From time savings to long-term costs, there’s a lot to consider. How will you know when it’s time to make that switch?

Here are some questions to ask yourself.

- Is the amount you’re spending on DTF transfers equal to the cost of the equipment?

- Could you produce better quality transfers on your own?

- Do you have space for the printer, shaker and dryer?

Your answers will reveal a lot about where you are with DTF, and which option is right for you.

Thank you for joining us as we take a closer look at the differences between in-house printing and outsourcing direct to film transfers. If you’d like more info about DTF, stay tuned – our next article is all about the new standards that DTF technology has set for our industry.